LIQUID/GAS EXCHANGERS

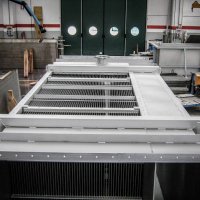

The exchangers built by FIC SpA with Pillow Plate technology for heat recovery boast a consolidated and long series of references in various industrial sectors. They consist of a series of Dimple Plates/Pillow Plates, in number and size that varies depending on the process parameters, enclosed in a casing with a normally rectangular or circular section.

They are designed for liquid/gas exchange , particularly suitable in situations where the geometry of the plates can provide indisputable advantages. Some typical cases:

- when there are hot fumes with medium or high relative humidity content, with the Dimple Plates it is possible to obtain high heat exchange coefficients in condensation conditions typical of these processes (for example in the paper mill, in the Paper Machines Hall downstream of the air exchange section -air);

- when in the gaseous streams of certain production processes there are non-negligible dust or fiber contents as the construction geometry of the FIC SpA exchangers allows for easy and quick cleaning, without the need for costly plant downtime and maintenance (for example in cement factories , or in wood treatment plants );

- when it is necessary to keep the level of pressure drops on the flue gas side as low as possible (to reduce energy consumption linked to the fans and also their investment costs);

- when it is necessary to condense polluting components or those that cause environmental problems (odours) , as the condensation process is greatly facilitated by the geometry of the Pillow Plates (e.g. animal food or feed production plants ).

In some cases the exchanger is not equipped with a casing, in the case in which it must be inserted into existing tanks or vessels, for example the case of distillation column head condensers , or in the case of thermal conditioning of particular fluids (oils, hydrocarbons etc).

FIC SpA also has the Process Therm in its range of exchangers . This is derived from the exchangers with casing and in addition is equipped with sections for conveying incoming and outgoing air , in turn integrated with service equipment such as washing system (pipes and nozzles), demister, manholes and more.

Process Therms are used in particular when both relative humidity and dust are present in the gaseous stream: a typical example is that of spray-drying systems for the production of powdered milk : with the Process-Therm it is possible to recover part of the energy from the exhausted process air which would otherwise be lost to the atmosphere, and which is used to pre-heat the fresh process air entering the system.

FIC SpA is able to carry out the thermal and construction sizing of both sections, downstream and upstream. FIC SpA exchangers can be built with all types of stainless or duplex steel, and for operating conditions that fall within a wide range of pressure and temperature. They are designed using the calculation codes linked to the PED 2014/68/EU regulation and in compliance with AD2000, ASME, EN calculation codes.

RECOMMENDED BECAUSE

- Heat recovery

- Paper sector

- Odor elimination

- Reduce pressure drops

- Design flexibility

- Coupling with spray dryers

- Processes with the presence of dust.

BUSINESS SECTORS

Heat recovery, Process Therm, flue condensers is particularly suitable for: