Energy Solutions

Today’s architects are faced with a difficult task – how best to design buildings that meet up-to-date energy codes while still keeping costs down and clients happy. Advancements in filtration technology make it possible to conserve energy, improve indoor environmental quality, and dramatically reduce ongoing utility and operating costs. Based on detailed monitoring of the ASHRAE Headquarters renovation in Atlanta, Dynamic V8 Air Cleaning Systems saved an average of almost 7 kWh of fan energy per square foot.

Dynamic provides three main Energy Solutions which reduce energy consumption and ongoing operating costs. They can also favorably influence HVAC equipment selection:

- Reducing Static Pressure

- Reducing Fan Energy

- Reducing Outside Air

HVAC accounts for about 40 percent of the energy used in U.S. commercial and residential buildings, making HVAC systems a good target for cost reductions and savings on a facility's annual operating budget. In new buildings, according to the U.S. Department of Energy, adopting energy-efficient design and technologies - in HVAC and other areas – can cut energy costs by as much as 50 percent. And in existing buildings, renovations that replace older systems with more efficient technology can yield savings of up to 30 percent.

HVAC accounts for about 40 percent of the energy used in U.S. commercial and residential buildings, making HVAC systems a good target for cost reductions and savings on a facility's annual operating budget. In new buildings, according to the U.S. Department of Energy, adopting energy-efficient design and technologies - in HVAC and other areas – can cut energy costs by as much as 50 percent. And in existing buildings, renovations that replace older systems with more efficient technology can yield savings of up to 30 percent.

1. Lower Static Pressure

An HVAC system’s energy efficiency depends in large part to the system pressure drop: the higher the filter’s pressure drop, the harder the HVAC system motor(s) need to work to deliver the required air flow. Reducing system pressure drop has one of the greatest impacts on energy costs. The development of new filter media like that used in the Dynamic V8 Air Cleaning System has given the industry a chance to produce lower pressure drops while maintaining high particle capture efficiencies. This provides the ability to improve IAQ and reduce electricity costs simultaneously.

In existing buildings, switching to lower pressure drop filters is one of the easiest changes building owners and facility managers can make to reduce energy costs. That’s because with a lower pressure drop filter, the HVAC system motor needs to overcome less resistance to deliver the required air flow, thus reducing the motor’s energy consumption. The cost of energy far outweighs the cost of the filter itself. In fact, energy costs can be 4 to 10 times the initial filter cost of higher efficiency final filters.

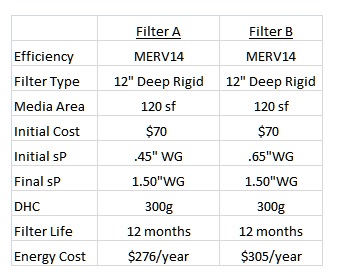

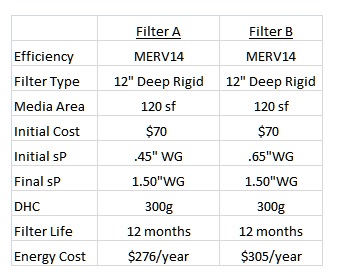

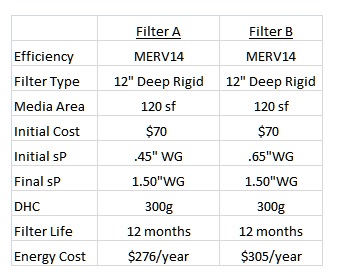

The following figures illustrate the effect of a filter’s pressure drop on annual energy costs. You will note that Filter A and Filter B are identical except for the initial pressure drop. In a typical scenario, many might use initial cost as the primary criteria in choosing one of these filters over the other. But as the example shows, this won’t result in the correct filter choice in maximizing long-term energy savings. In the example, initial costs are kept constant to illustrate the effect of just pressure drop on operating costs.

Calculation: Energy Consumption = Q*dP*t/n/1000 Assumes 24/7/365 operation, energy cost of $.08/kWh, fan motor, drive frequency (n) of 58 percent.

The lower pressure drop of Filter A saves approximately $29 in energy costs annually – about a 10 percent reduction in energy consumption. While an energy cost savings of $29 per year may not sound like a lot, keep in mind that those cost savings are per filter, not for an entire HVAC system. Most buildings contain many filters in each air handling unit, so savings can quickly add up.

2. Less Fan Energy

In an amendment within ASHRAE Standard 90.1, a standard was set for allowable brake horse power for each type of system and space use. Section 6.5 of the 2007 version of ASHRAE 90.1, (HVAC Air System Design and Control) sets allowances for brake horsepower based upon system type and its application. In many reviewed cases, the allowances are not able to be met with traditional filtration, making this approach, for some, the only method for compliance with Section 6.5 of the standard.

Lower static pressure corresponds directly to lower brake horsepower. Brake horsepower drives fan energy and so on. With Dynamic Air Cleaners, and using the prescriptive option under section 6.5.3 of ASHRAE 90.1, engineers can reduce energy and provide every customer with a payback worth investing in.

The construction industry has made great progress in implementing energy saving strategies that improve building efficiency and carbon footprint. There are various control and system strategies that will prove wise investments for building owners. Nearly all of them, however, are geared to reducing heating and cooling system consumption.

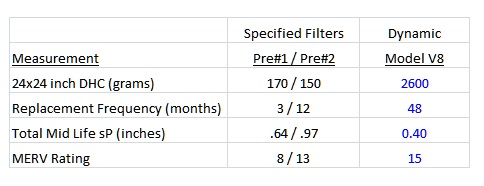

Dynamic Air Quality Solutions has contributed to fan energy reduction programs all over the world. In any building using pre and post filtration of MERV 8 and 13 or even higher, Dynamic can reduce mid-life static pressure by more than 1 inch and design static by more than 1.75 inches. This makes our systems an easy and effective tool for compliance to the new standard for measuring building airside efficiency. Like other aspects of ASHRAE, 90.1, the more the standard is exceeded, the higher the perceived building value and acceptance of performance. Ultimately, Dynamic Air Cleaners not only comply with the allowable adjustment for filtration - it can make investments in Dynamic air cleaning systems a no brainer!

Case in Point: In a recent energy audit of an office building in Boston with traditional filtration, 23 percent of the total annual electric consumed is HVAC fan energy. It was also calculated that 20 percent was HVAC cooling and heating. Imagine the impact of upgrading the filtration for this building from MERV 8 to MERV 13 and adding approximately 1.0 inches of mid-life static to the primary fans!

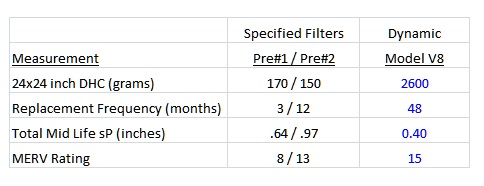

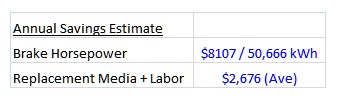

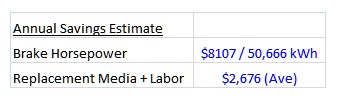

As you can see in the following example of a 34,000 cfm air handler and a $.16 blended utility rate, using Dynamic V8 Air Cleaners instead of 85% cartridge filters can save over $8,000/year in fan energy costs. Just from the reduction in static pressure in this model, design brake horsepower is reduced 14.3 bhp.

Technical Performance Deliverable:

Financial Deliverable:

Ask us for a free Return on Investment (ROI) analysis on your next project for a greener, cost effective design.

2. Less Fan Energy

In an amendment within ASHRAE Standard 90.1, a standard was set for allowable brake horse power for each type of system and space use. Section 6.5 of the 2007 version of ASHRAE 90.1, (HVAC Air System Design and Control) sets allowances for brake horsepower based upon system type and its application. In many reviewed cases, the allowances are not able to be met with traditional filtration, making this approach, for some, the only method for compliance with Section 6.5 of the standard.

Lower static pressure corresponds directly to lower brake horsepower. Brake horsepower drives fan energy and so on. With Dynamic Air Cleaners, and using the prescriptive option under section 6.5.3 of ASHRAE 90.1, engineers can reduce energy and provide every customer with a payback worth investing in.

The construction industry has made great progress in implementing energy saving strategies that improve building efficiency and carbon footprint. There are various control and system strategies that will prove wise investments for building owners. Nearly all of them, however, are geared to reducing heating and cooling system consumption.

Dynamic Air Quality Solutions has contributed to fan energy reduction programs all over the world. In any building using pre and post filtration of MERV 8 and 13 or even higher, Dynamic can reduce mid-life static pressure by more than 1 inch and design static by more than 1.75 inches. This makes our systems an easy and effective tool for compliance to the new standard for measuring building airside efficiency. Like other aspects of ASHRAE, 90.1, the more the standard is exceeded, the higher the perceived building value and acceptance of performance. Ultimately, Dynamic Air Cleaners not only comply with the allowable adjustment for filtration - it can make investments in Dynamic air cleaning systems a no brainer!

Case in Point: In a recent energy audit of an office building in Boston with traditional filtration, 23 percent of the total annual electric consumed is HVAC fan energy. It was also calculated that 20 percent was HVAC cooling and heating. Imagine the impact of upgrading the filtration for this building from MERV 8 to MERV 13 and adding approximately 1.0 inches of mid-life static to the primary fans!

As you can see in the following example of a 34,000 cfm air handler and a $.16 blended utility rate, using Dynamic V8 Air Cleaners instead of 85% cartridge filters can save over $8,000/year in fan energy costs. Just from the reduction in static pressure in this model, design brake horsepower is reduced 14.3 bhp.

Technical Performance Deliverable:

Financial Deliverable:

Ask us for a free Return on Investment (ROI) analysis on your next project for a greener, cost effective design.