Service & Maintenance Solutions

In addition to providing the ability to achieve the optimum point between power consumption and indoor air quality, Dynamic Air Cleaners offer three important Service and Maintenance Solutions:

- Longer Maintenance Intervals

- Reducing Operating Costs

- Physically Smaller Size for a Smaller Carbon Footprint

Longer Maintenance Intervals

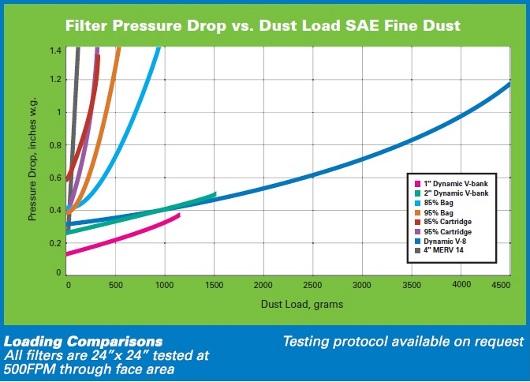

The best measurement of how long a filter will last (and its subsequent impact on static pressure), is Dust Holding Capacity. Since ASHRAE 52.2, the industry has seen passive filter manufacturers promote high MERV ratings with very low initial static pressures. However, because 52.2 does not require filter manufacturers to publish dust holding capacity data, it is easy to misinterpret a filter's true deliverable.

For example, a 2 inch, MERV 13 filter holds approximately 40 grams of dust before hitting its design static pressure of 1.4 inches w.g. Therefore, if the average building produces 130 grams of dust per cubic meter each month or 48 grams per 24x24 inch filter, you'd have to replace a 2 inch deep, MERV 13 filter monthly, a 4 inch deep MERV 13 filter bi-monthly, etc. to keep the static below 1.4 inches and maintain a mid-life static pressure of around .9 inches...not including any impact from a pre-filter. A higher dust holding capacity means the filter will operate longer at lower static pressures. The Dynamic V8 is tested to hold 2600 grams of dust at its recommended change state of .6 inches or twice its initial static pressure.

One of the best examples of superior dust holding capacity is found at the ASHRAE headquarters in Atlanta, GA where all of the HVAC systems operate with Dynamic V8 Air Cleaning Systems. In the primary air handlers, the static pressure climbed a mere .1 inches after three years of operation, producing approximately .4 inches of static at design CFM. If you were to compare that to a traditional application of 30 percent pre filters and 85 percent (MERV 13) post filters, you'd see a savings of around .75 inches in mid-life static. In addition, the Dynamic V8s save three or four changes per year on the pre-filters and once per year on the posts. So, Dynamic has saved 15 filter changes in just 3 short years!

The dramatic loading characteristic of the Dynamic V8 Air Cleaning System means a typical maintenance cycle of over three years. And that means no pre-filter or quarterly replacements and no more 9 to 12 month final filter replacements. Fewer media changes also means less material used and a smaller environmental footprint for the building.

Reducing Operating Costs

Dynamic Air Cleaners can potentially reduce a building's total operating costs by 15% or more when conventional filters are replaced with Dynamic Air Cleaners. The cost of filtration contains hidden costs that are often overlooked such as the costs associated with purchasing, receiving, labor, storage, and disposal. These costs, when combined with the HVAC system energy consumption, can add up to as much as 75% of a building's total operating costs. Dynamic Air Quality Solutions can reduce this by one third, for a reduction of about 15% of the building’s total operating costs.

Let’s look at a rundown of the basic work that goes into routine filter service:

- Filter replacement schedules should be properly maintained.

- System static pressures should be monitored to ensure optimum operating conditions.

- Prior to the service date, orders must be generated and placed for replacement filters.

- Upon arrival, the filters must be unloaded, inspected, received, and sorted.

- Conventional bag or cartridge filters can take up a lot of space which people must work around until the service date.

- The maintenance team or filter service company performs the actual filter replacements. Labor costs are increased when filters are bulky and filter racks are difficult to access.

- And finally, the old, dirty filters are disposed of or hauled away.

In total, when considering energy, materials and all the associated hidden costs, filters represent a big chunk of a building’s total operating costs. When compared to 80-90% efficient bag or cartridge filter systems, energy-saving polarized-media alternatives can yield savings of as much as 2/3 of the cost of filtration which can be equated to roughly 15% of a buildings total operating cost.

Physically Smaller Size for a Smaller Carbon Footprint

Dynamic replacement media pads are a fraction of the weight and size of conventional high efficiency bag or cartridge filters. This means replacement filters take up less storage space, they are much easier to handle in tight spaces, and easier to discard or recycle.

Dynamic V8 replacement media (left) does the same job as the 24” x 24” conventional cartridge filters shown on the right...but also providing better filtration, lower static pressure, longer maintenance intervals, and taking up far less space