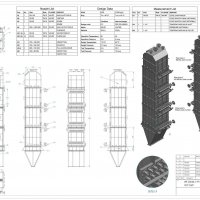

HEAT TREATMENT OF GRANULAR OR POWDERY SOLIDS

Thanks to the great experience in the design and construction of heat exchangers based on the Pillow Plate concept, FIC is able to present itself on the Bulk Solid Heat Exchangers market with extreme competence. FIC SpA's Bulk Solid Heat Exchangers are designed using dedicated calculation software , both for thermal and mechanical sizing and are built following rigorous standards and a series of trials and tests in order to deliver to its customers a completely reliable product, efficient and effective.

The product is used in the heat treatment of granular or powdery solids.

Thanks to the use of Pillow Plates, Bulk Solid Heat Exchangers are able to guarantee considerable performance advantages compared to traditional systems (e.g. compared to fluidized bed systems) as the heat treatment of the product occurs indirectly and more checked.

These products are used in various industrial sectors : in the chemical sector for the cooling of fertilizers - Urea, NPK, KCl, Phosphates etc - during the production cycle or for the thermal conditioning of inorganic salts - carbonates, borates, sulphates etc.

In the food sector for the cooling of sugar , coffee, for the heat treatment of soya or sunflower seeds in the squeezing processes.

In the metallurgical sector for the cooling of foundry sand . In the energy world for heating plant seeds for the production of biodiesel and many others.

FIC SpA can supply these exchangers equipped with the equipment related to their complete operation, including therefore the modules for the management of heat transfer fluids, the control and management systems and everything necessary to have a complete turnkey system.

FIC SpA can also develop field tests with its customers , thanks to pilot plants capable of reproducing on a small scale all the situations that can occur in an industrial context, in order to identify the best solution depending on the individual characteristics of each specific plant.

RECOMMENDED BECAUSE

- Fertilizers

- Sugar

- Seeds for vegetable oils

- Foundry sands

- Cooling before packing

- Energy saving

- Operational flexibility

- Possibility of integrations

- Retrofitting existing systems.

BUSINESS SECTORS

Bulk Solid Heat Exchangers is particularly suitable for: