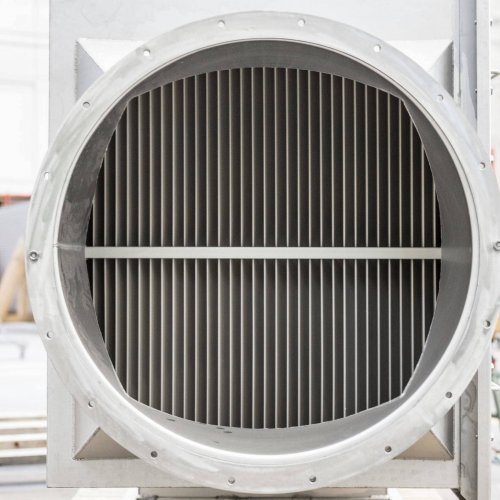

GAS/GAS AND GAS/LIQUID HEAT EXCHANGE

The heat exchangers designed and built by FIC represent the ideal solution in many industrial applications and processes. In fact, their use can cover a vast operating range of pressures, temperatures and types of fluids.

The exchangers can be used for both gas/gas, gas/liquid, liquid/liquid exchange; in all cases an undoubted advantage in their use occurs when the fluid outside the plate has non-negligible fouling factors. In fact, thanks to complete accessibility, the plates can be easily cleaned, minimizing equipment maintenance times.

In addition to this aspect, Pillow Plates, compared to tubes, guarantee important advantages in terms of exchange surface, greater for the same volume occupied and from the point of view of the heat exchange coefficient which, thanks to the high turbulence inside plate, is much higher.

In certain fluid dynamic configurations these aspects are particularly accentuated, for example in processes with thin film evaporation.

FIC heat exchangers can be integrated directly into equipment such as columns, vessels and the like or constitute stand-alone units, in which case the solution normally used is the shell&plate; in the latter case the exchanger is also sized from a structural point of view, possibly also with FEM analysis.

FIC can build exchangers using both austenitic steels (AISI 304, 304L, 316L, 316Ti, 321, 904L) and high alloy and duplex steels (SMO 254, SAF2205, 2307, LDX 2101, etc.).

Typical applications of these exchangers are:

- evaporators for multiple effect systems

- thin film evaporators

- rectification and distillation column head condensers

- internals of crystallizers

- interiors of chemical reactors

- chillers for wastewater treatment plants

- process current recuperators and preheaters

- Thin film chillers on high-power heat pump systems

- sludge dryers and thickeners.

RECOMMENDED BECAUSE

Particularly suitable for:

- Versatility

- liquid/liquid, liquid-gas, gas/gas exchange

- chemical and petrochemical industry

- multiple effect evaporator

- column head condenser

- heat recovery

- chemical reactors.

BUSINESS SECTORS

FIC exchangers for other applications is particularly suitable for: