Dynamic Activated Carbon Matrix

Dynamic Activated Carbon Matrix (ACM) systems represent the perfect solution for a wide range of applications. Dynamic ACM technology eliminates unwanted odors, removes corrosive gases, removes target contaminants, and supplies purified air more efficiently.

Activated carbon filtration systems have been used for decades in critical applications for the removal of harmful odors and chemical gases. Carbon works through a process called adsorption – the deposition of a gas on solid. Because of its molecular structure, Carbon is an excellent natural adsorber. For this reason, hospitals, museums, and clean manufacturing facilities all rely on the power of activated carbon to capture

Dynamic Activated Carbon Matrix is housed in either a plastic or metallic frame and is available in nominal depths of one, two, four and six inches as standard. Modules are designed to fit in a side-access filter track or a Type 8 filter frame, and are available with or without a header.

Innovative air purification technology does it better

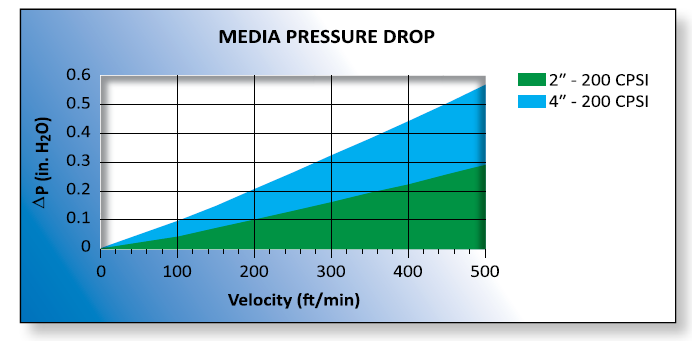

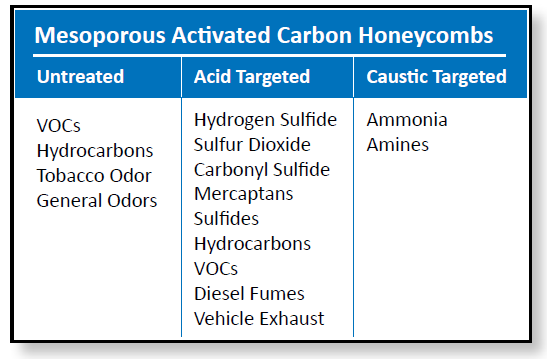

Dynamic Activated Carbon Matrix material was developed using advanced composites and extrusion technologies to increase carbon utilization. The patented, revolutionary design utilizes an activated carbon/ceramic honeycomb matrix that features unrestrictive air channels to provide a pathway for air to flow with low resistance. The carbon and ceramic are tightly bound together, eliminating dust shedding and the need for downstream filters. Today, Dynamic ACM systems are the perfect solution for a wide range of applications. Dynamic Activated Carbon Matrix systems require less space, operate with a very low pressure drop and require no post filters, enabling Dynamic Activated Carbon Matrix systems to be used today in a variety of applications where carbon filtration was previously not an option. State-of-the-art carbon technology eliminates unwanted odors, removes corrosive gases, removes target contaminants, and supplies purified air more efficiently.

Dynamic Activated Carbon Matrix systems can be used in:

- Specialty Applications: such as museums, archives, hospitals, labs, manufacturing, embassies.

- Problem Applications: to address issues such as entrainment of kitchen fumes or engine exhaust fumes.

- General Applications: cleaning the air of gas phase contaminants in commercial buildings or for reduced outdoor air applications.

- Industrial Applications: including pulp and paper, petrochemical plants and refineries, as well as municipal and private waste water treatment plants.

Outstanding Performance:

Activated carbon and longevity are impacted by the weight of the carbon and the mass transfer zone (MTZ) length. MTZ impacts the efficiency and more carbon increases the total capacity for odor removal. One gram of activated carbon has 10,000 square feet of internal surface area. One pound of activated carbon has a surface area equal to about 125 acres. Based on the contaminants of concern and their concentration levels, the media life for Dynamic Activated Carbon Matrix is predictable. In addition, the media can be engineered on a job-by-job basis to meet specific performance requirements such as static pressure drop, maximum face velocity and residence time. Common target contaminants include Hydrogen Sulfide, Sulfur Dioxide and other acid gases and odors.

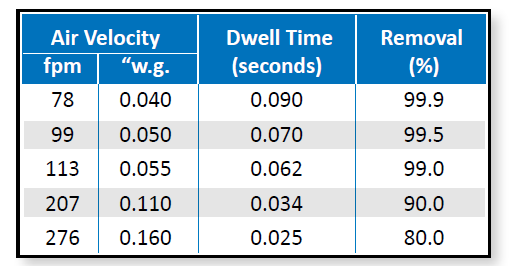

Dynamic Activated Carbon Matrix is engineered to deliver an 80.0% to 90.0% upstream/downstream removal. The chart above shows removal of Xylene which is has similarrepresentative characteristics of vehicle exhaust emissions and common VOCs

Physical Properties

- Density – 26.6 lb/ft3

- Crush Strength – 300 psi minimum

- Dust-free under normal operation

Removal Capacity

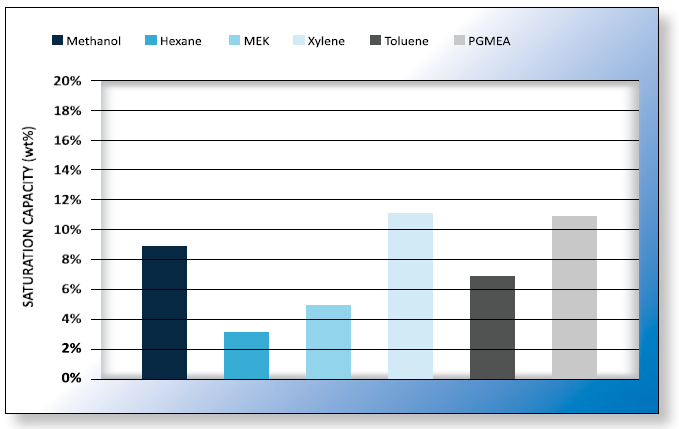

- Hydrogen Sulfide - 30-40% by weight

- Sulfur Dioxide – 15-20% by weight

- Xylene – 13% by weight saturation

- Toluene – 9-20% by weight saturation

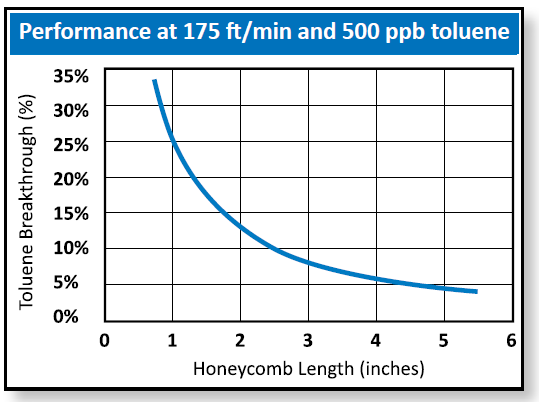

The graph above shows VOC removal using 500 ppb toluene at 175 ft/min. Toluene is a good indicator of VOCs with a vapor pressure <26 mmHg.

Unsurpassed Versatility:

- Suitable for high airflow applications (150-250 fpm).

- Suitable for high temperature applications up to 500°F.

- Suitable for damp conditions up to 99% RH.

- Can be mounted horizontally or vertically with airflow in either direction.

- Maximum gaseous contaminant removal and protection from gas-phase contaminants.

- Can be installed and disposed of without the need for any special safety precautions.

Dynamic Activated Carbon Matrix offers many advantages over pellet based systems

The most widely used commercial carbon filtration systems consist of 1”-2” deep trays filled with carbon pellets. Large arrays are typically used and air handling systems require powerful fans to overcome very high resistance to airflow. And because carbon pellet systems can shed carbon dust, downstream filters become necessary which can further restrict airflow.

Extended life pellets were introduced in the marketplace over a decade ago, and are formulated to maintain their shape and integrity for a period of four years of operation. Over time, pellets are subject to diurnal and seasonal swings in temperature and humidity, as well as constant vibrations. Granular residue will eventually plugs screen material and lead to channeling in the media, which can allow untreated, contaminant laden air to enter the protected space.

Dynamic Activated Carbon Matrix systems can be retrofitted into existing pellet cassettes (V-banks) and HVAC units and provide significant advantages including:

- Dynamic Activated Carbon Matrix systems have up to a 60% lower pressure drop, reducing blower horsepower by up to 50% compared to pellet systems.

- Half the size and a fraction of the weight of a pellet based system.

- Easier to use and maintain because they do not require vacuum trucks, pellet handling or confined space entry that is associated with media change out.

- Dynamic Activated Carbon Matrix systems have significantly smaller footprints and much lower weights, making installation easier and less costly than traditional pellet systems.

- Fast and effective contact at velocities up to six times greater than traditional pelletized carbon beds.

- Unlike pellet based systems which typically break through after about 66% utilization of the pellet media, properly rotated Dynamic Activated Carbon Matrix systems use 100% of the media as the media modules are replaced over time.

Engineered Solutions

Dynamic Activated Carbon Matrix systems can provide a purified air cleaning solution to prevent corrosion of valuable electronic equipment in process industries — helping reduce downtime and costly repairs. In addition, Dynamic Activated Carbon Matrix removes odors and protects the environment from subsequent destruction of dilute solvents. Dynamic Air Quality Solutions will provide a comprehensive solution of equipment, activated carbons, service, and technical know-how. Backed by state-of-the art research capabilities, our team of scientists and engineers understands the unique chemistry between the air we breathe and its effects on your environment.